Imagine

a power station that’s the size of a suitcase!

That’s what President Obama’s vision is for his first manufacturing innovation

hub, the "Next Generation Power

Electronics Institute."

The North Carolina hub will jumpstart next generation power electronics, so those

ever-smaller devices like tablets and smart phones can become even tinier,

faster, cheaper and more efficient. They are

also integral to electric vehicles, industrial motors and many clean energy

technologies, such as solar and wind inverters that connect them to the grid. The

goal is for these “wide bandgap semiconductors” – 10 times more powerful

that current chips on the market – to

be cost-competitive with silicon semiconductors in five years.

Two other hubs will follow,

all designed to continue his efforts to make the US a the leader on advanced

manufacturing, while creating the well-paying jobs a growing middle class

requires. Together, they will form the President’s National Network of Manufacturing

Innovation.

“In the last century, silicon semiconductors

transformed computing, communication and energy industries, giving individuals

and businesses more and more powerful devices that were once unimaginable,”

says the White House. “For nearly 50 years, silicon chips have been the basis of power

electronics. However, as clean energy technologies and the electronics industry

has advanced, silicon chips are reaching their limits in power conversion —

resulting in wasted heat and higher energy consumption,” explains Ernest Moniz,

Secretary of Energy.

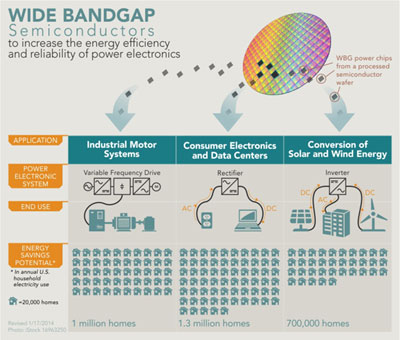

Next generation semiconductors, called wide bandgap semiconductors, can operate

at higher temperatures, voltages and frequencies, giving them the potential to

vastly increase performance while using much less energy. They eliminate up to

90% of the power losses in electricity conversion, for example.

“This in turn means that

power electronics can be smaller because they need fewer semiconductor chips,

and the technologies that rely on power electronics – like electric vehicle

chargers, consumer appliances and LEDs – will perform better, be more

efficient and cost less,” Moniz adds.

With a strong wide bandgap semiconductor manufacturing base, the

US can lead in some of the world’s largest and fastest growing

markets from consumer appliances and industrial-scale equipment to

telecommunications and clean energy technologies, he says.

Led by North Carolina State University, a consortium

of local businesses, universities and federal agencies will co-invest to bridge

the gap between applied research and product development in this arena. North

Carolina is home to world leaders in wide band gap semiconductors on the

manufacturing, materials and research sides.

The Department of Energy is

awarding the hub $70 million over five years, matched by at least that much by

the team of seven universities and 18 companies – including cleantech leaders Cree

and ABB – that have signed on. The state is contributing $10 million.

18 Companies: ABB, APEI, Avogy, Cree, Delphi, Delta Products, DfR

Solutions, Gridbridge, Hesse Mechantronics, II-VI, IQE, John Deere, Monolith

Semiconductor, RF Micro Devices, Toshiba International, Transphorm, USCi, Vacon.

7 Universities and Labs: North Carolina State, University of North Carolina,

Arizona State University, Florida State University, University of California at

Santa Barbara, Virginia Polytechnic Institute, National Renewable Energy

Lab.

First proposed in last year’s

State of the Union address, the three hubs are

being selected using a competitive process. While the Department of Energy leads

the North Carolina hub, the Department of Defense will lead the other two hubs,

to be announced in the coming weeks. One will focus on Digital Manufacturing

and Design Innovation and the other, Lightweight and Modern Metals

Manufacturing. In all, five federal agencies are committing $200 million for

the three hubs: Defense, Energy,

Commerce, NASA, and the National Science Foundation.

All the hubs are conceived as “teaching

factories” – offering education and workforce training, and helping companies –

especially small manufacturers – get access to the

equipment and cutting edge capabilities they need to invent, design, test, and

pilot new semiconductor chips and devices. The institute will also pair

chip designers and manufacturers with large power electronic manufacturers

and suppliers, such as John Deere and Delphi, to bring these technologies to

market faster, says Moniz. The ultimate goal for each hub is to become a global

center of excellence, workforce and education programs.

President Obama’s vision is for a national

network of up to 45 manufacturing innovation institutes, but that require Congress

to pass supportive legislation. This summer, bipartisan bills were introduced

in the House and Senate that would create this network: Senators Brown (D-OH)

and Blunt (R-MO); Reps Reed (R-NY) and Kennedy (D-MA).

The Other Two Hubs:

Digital Manufacturing

and Design Innovation: Advanced design and

manufacturing tools that are digitally integrated and networked with supply

chains can lead to ‘factories of the future’ forming an agile U.S. industrial

base with significant speed to market advantage. A national institute focusing

on the development of novel model-based design methods, virtual manufacturing

tools, and sensor and robotics-based manufacturing networks will accelerate innovation

in digital manufacturing, increasing U.S. competitiveness.

Lightweight and

Modern Metals Manufacturing: Advanced lightweight metals have mechanical and electrical

properties comparable to traditional materials while enabling much lighter

components and products. A national institute will make the U.S. more

competitive by scaling-up research to accelerate market expansion for products

such as wind turbines, medical devices, engines, armored combat vehicles, and

airframes, and lead to significant reductions in manufacturing and energy

costs.

Here is the Next

Generation Power Electronics Institute website: