It may not be exciting to read about a new energy efficiency standard, but setting ever-more stringent requirements for appliances and equipment is one of the most powerful tools for cutting energy use in the US.

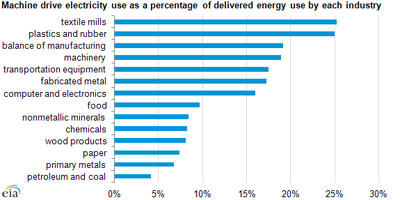

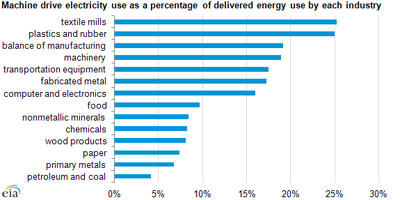

This is especially true when it comes to motors – which consume about 50% of all industrial electricity, according to the US Energy Information Administration (EIA).

The Department of Energy (DOE) is proposing long-overdue efficiency standards for electric motors, which operate everything from fans and pumps used for irrigation and wastewater treatment plants to elevators and conveyor belts.

Over 30 years, these standards are expected to save 1 trillion kilowatt hours of electricity – enough to power almost every US home for a year, along with savings to businesses of $23.3 billion. In terms of carbon emissions, the savings equal taking 82 million cars off the road.

"The wide use of motors across many industries results in a substantial impact on the demand placed on power grids," says EIA, which projects that this increased efficiency will offset that of industrial output, resulting in relatively flat levels of electricity consumption by machine drives.

And the impact will be felt across the world, where US standards are influencing overseas manufacturers to improve the efficiency of their motors, too.

"Rather than trying to set slightly higher standards for electric motors already covered by two rounds of previous U.S. standards, we recommended that DOE expand the scope of coverage to many motor types not previously regulated," says American Council for an Energy Efficient Economy (ACEEE).

This approach made sense to both manufacturers and environmental groups, all of which were involved in developing the new standards. Manufacturers like the fact that they can apply the proven designs they developed for existing regulated motors to more kinds of motors.

Efficiency standards for motors now apply to almost all kinds of motors – from 1-500 horsepower.

When Secretary Moniz took over DOE this year he promised to make efficiency more of a priority. Since then he’s been moving on a series of efficiency standards that have long been delayed, such as commercial refrigeration equipment, furnace fans and metal halide light fixtures.

Last year, the US used less energy than in 1999 and that’s with an economy that’s grown more than 25% since then. In fact, efficiency has contributed more to meeting US energy demand than all other resources combined over the past 40 years – more than coal, oil, or nuclear, concludes a report from the Natural Resources Defense Council (NRDC).

Loading...

Loading...